FINETECH Pico RS BGA

System for welding/dewelding of surface-mounted components, and BGA coating.

The key elements that allow the system to rework entire BGA components, to simple solder balls, including small passives (0201, with current nozzles) are:

- Precise opto-mechanical alignment between the "head" (nozzle) and the target (PCB, component)

- enabled by an optical beam splitter and calibrated mechanics;

- The vacuum brought by a microscopic hole on the head, allowing to lift a component;

- Hot air at controlled and adjustable temperature and flow.

Note

It is possible to have heads and stencil manufactured adapted to our needs by the company Finetech

Specifications

| Parameter | Value | Note |

|---|---|---|

Placement accuracy | 5 µm | |

Min. field of view | 11.5 mm x 8.6 mm | |

Max. field of view | 69 mm x 53 mm | |

Component size min. | .125 mm x.12 mm | depending on available tool (head/stencil) |

Max. component size | 40 mm x 40 mm | depending on available tool (head/stencil) |

External thermocouple (opt.) | 2 max | for process adjustment/control |

Pictures

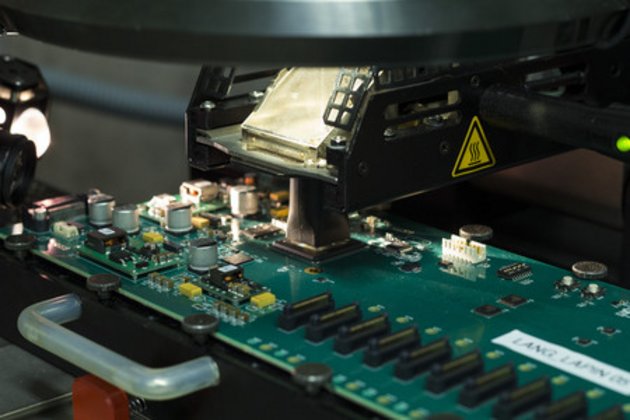

The equipment as a whole