CALTEX RX-100-BGA

With the innovative 3D rotation view, in addition to the 90° observation mirror for BGA/QFP, this device offers unprecedented BGA inspection capability. Quality control and defect analysis is easily done using the camera and tools. The system is easy to use and extremely robust for a production environment. Real-time view of inspection, image capture of defects for documentation and measurement of the size of the balls of a BGA.

- Weld checks

- Variable working distance

- 360° angle view (30°)

- High Resolution 2MP SONY CCD Color Camera

- 3x magnification à 100x

- Complete software for image processing

Applications

- SMT Weld Inspection

- Inspection of the BGA

- Inspection of the inside of Thru-holes

- Inspection and documentation of metal, plastic and other parts

- Failure analysis

Specifications

| Parameter | Value |

|---|---|

Zoom Magnification | 15x-100x |

Zoom Ratio | 1:6.5 |

Field of view | 2.4 mm à 100x jusqu'à 16 mm à 15X |

Angle of view | 0° direct view and 20° angular view |

Working distance - direct view | (15-100x) : 103 mm |

Working distance - angular view 30° | (15-100x) : 45 mm |

Measurement accuracy (software) | 10µ à 15x, 1.6µ à 100x |

Examples of uses

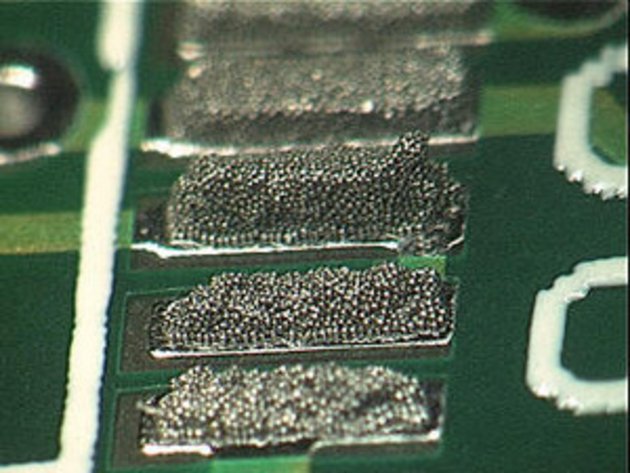

Solder paste inspection

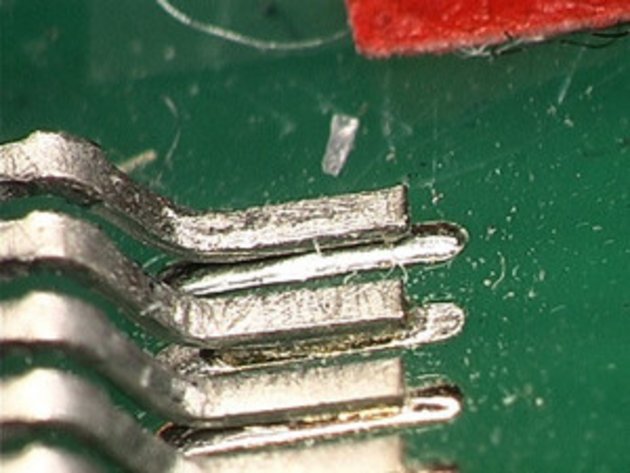

Fine Pitch Component Inspection

Using the Mirror for BGA Inspection

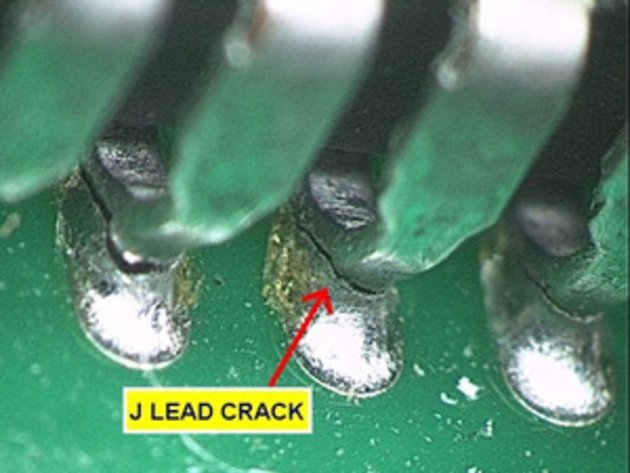

J-Lead welding inspection

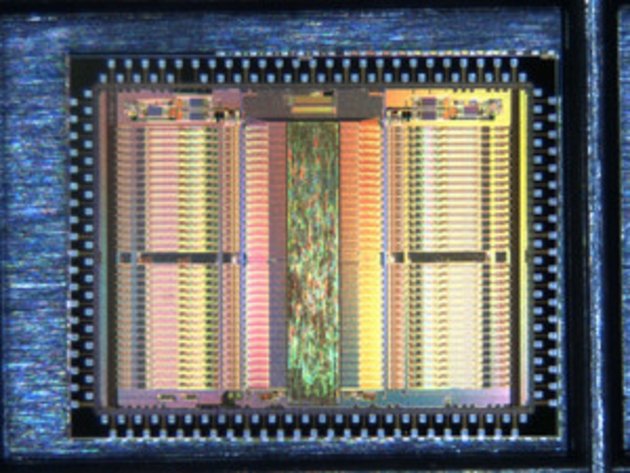

Photo of chip

(here: Photo ASIC ICFSHFE3 (4.56mm x 5.887 mm))