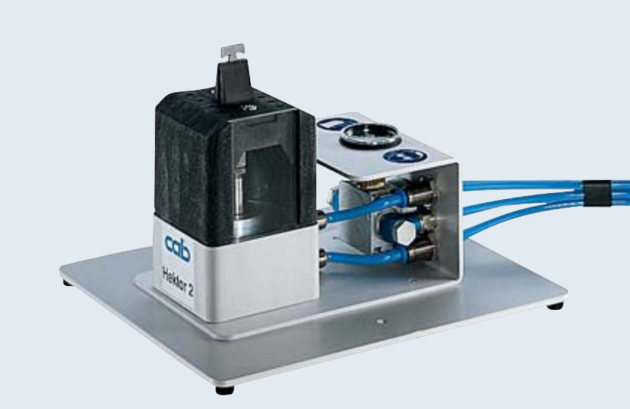

CAB Hektor 2

PCBs are separated carefully and quickly, off-cuts are removed precisely and smoothly. A two-part matrix enables the different blades to be assembled resp. exchanged easily.

Off-cuts are punched out with the help of a compressed air cylinder. The operating pressure can be set on the unit.

PCBs are positioned with their milled groove over the blade onto the matrix. The off-cut is fed below the punch blade. A foot switch triggers the punching and the off-cut is collected in the bottom tool.

Specification

| Parameter | Value |

|---|---|

| Material | FR4 |

| Material thickness | up to 2,5 mm |

| Separation method | Manual, punch blade |